The highest overall performance of any decelerator sled availa ble at any price

ble at any price

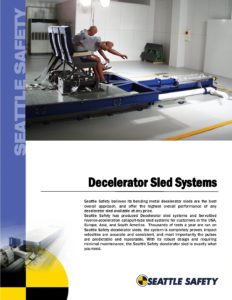

The advent of automobile safety regulations in the 1960’s created demand for devices that could economically and accurately assess the performance of safety restraint systems without requiring the destruction of a vehicle. Sled systems to assess safety restraint components can either be decelerator type, where the sled is gently accelerated to an impact velocity and then stopped in a controlled manner, or reverse acceleration, with the physics reversed. Over the years both approaches have been widely used. Reverse acceleration sleds have the advantage of a stationary sled prior to impact, eliminating any possibility of dummy movement that can adversely affect test repeatability. Deceleration sleds can more easily perform some specialized tests, such as tests that involve simulation of pre-impact braking. Decelerator sleds also are generally less expensive to produce, operate, and maintain. When carefully designed to minimize pre-impact dummy movement, deceleration sleds can provide superb results.

Various decelerator sled design approaches are in use in industry. Decelerators that use a probe penetrating a contoured urethane tube are in wide use for regulatory testing, as they are inexpensive to build and use. These systems are limited in the type of pulses that can be produced, however. Hydraulic ‘water brake’ and ‘wedge’ decelerators are also produced. Probably the most common decelerator type uses energy absorption by bending metal to create the pulse, and the Seattle Safety system falls in this group.

Seattle Safety believes that bending metal is the best overall approach for decelerator sleds, and that the Seattle Safety sled has the highest overall performance of any decelerator sled available at any price. At the end of this Proposal there is a discussion of the relative technical merits of metal-bending and hydraulic systems.

Seattle Safety has produced ten decelerator sled systems for customers in the USA, Europe, and Asia, and has produced two servo-controlled accelerator systems in cooperation with another company. Thousands of tests a year are run on Seattle Safety decelerator sleds, and the system is completely proven. The impact velocities are accurate and consistent. The pulses are predictable and repeatable. The equipment is easy to use and strong, as evidenced by our very rare sale of spare parts.

Decelerator Sled Specifications

|

System |

Peak |

Stroke |

Peak g |

Maximum Energy |

Maximum Velocity |

Maximum |

|

D1000-3.7 |

1000KN |

1.9m |

115g |

340,000 N-m |

100 kph |

4000kg |

|

D1000-3.0 |

1000KN |

1.9m |

187g |

340,000 N-m |

127 kph |

4000kg |

|

D780-3.7 |

780KN |

1.9m |

90g |

285,000 N-m |

91 kph |

4000kg |

|

D780-3.0 |

780KN (175,000 lb) |

1.9m |

146g |

285,000 N-m |

116 kph |

4000kg |

|

D400-3.0 |

400KN |

1.6m |

82g |

147,000 N-m |

87 kph |

2000kg |

|

D400-2.5 |

400KN |

1.6m |

120g |

147,000 N-m |

105 kph |

2000kg |

Performance specifications are subject to conditions.