Add the ability to simulate pitch on your existing sled

The Seattle Safety Dynamic Pitch Simulator is an economical add-on accessory to sled test systems. Current lab managers can add pitch simulation without replacing their systems, and new customers can buy with confidence knowing they can add the simulator any time in the future.

Adding pitch simulation to sled test systems for full frontal impact testing can improve the correlation of occupant injury performance between sled tests and barrier tests, providing engineers with better design data resulting in better engineering and safer vehicles.

- Add proven pitching simulation any time with breakthrough simplicity and minimal investment

- Only minor test lab modifications required – pitch simulator installs directly to existing sled and reaction block

- Does not compromise non-pitch testing – pitch fixtures can be easily removed in an hour or less to maximize payloads, camera views, and access

- Proven repeatable trajectory using fixed-path guidance eliminates the need for expensive control systems

Only minor modifications required

The Dynamic Pitch Simulator can be installed on existing sled test systems with only minor test lab modifications.

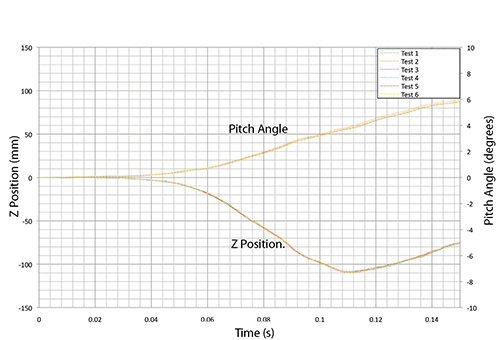

Proven repeatable trajectory

The pitch motion is highly accurate and repeatable due to the fixed-path guidance, eliminating the need for expensive control systems.

Most pitching profiles can be simulated accurately using the seven standard guides provided with the pitch simulator system. The system selects the correct guides for the test and electronically positions them prior to the test.

With fixed-path guides, the horizontal pulse is the only tuning variable; sled pulse and pitch performance are quickly achieved using existing sled pulse tuning algorithms.

Six independent tests overlaid to illustrate excellent repeatability.

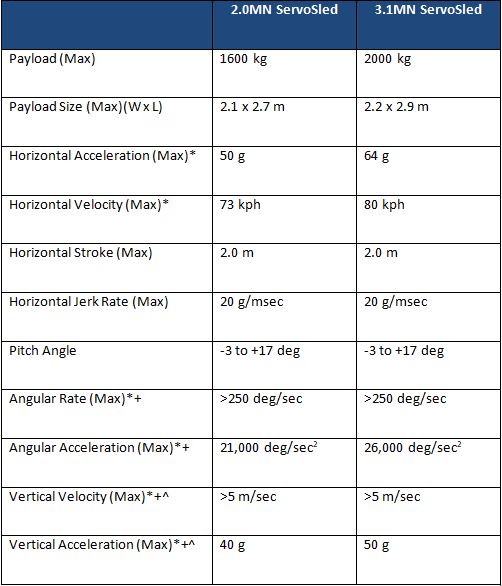

Performance Specifications

Note: any performance data contained herein is operating-condition dependent.

* At 1,000 kg payload.

+ Values are a function of guide geometry and are limited only by the structural strength of the system.

^ Measured at center of gravity.